PANEL TO PANEL CONNECTIONS

Panel to panel connections form wall and floor assemblies as it involves connecting panels along their longitudinal edges. These are usually established mostly on site. Panel to panel connections must be designed to resist in-plane shear and out-of-plane bending.

Below are the various panel to panel connection types:

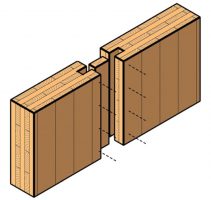

1. Internal splines

Here, a thin CLT or plywood is used to form this connection. However, the profiling of the panel at the plant is necessary prior to delivery on site. Connection between the splines and the two panel edges can be established using self-tapping screws, wood screws or nails. Th use of internal splines provides a double shear connection.

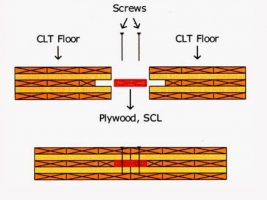

2. Single surface splines

Panel edges are profiled to take a strip/spline of lumber or SCL such as LVL, PSL or laminated strand lumber (LSL). Due to the single shear connection involved, this connection detail is typically inferior to the internal spline previously described.

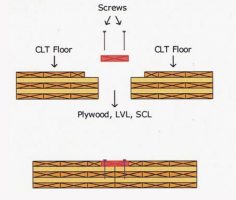

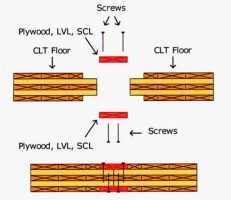

3. Double surface splines

Like a single surface spline, this has a double spline used to increase the connection strength and stiffness. However, this connection requires more machining and time for erection since there is a need to attach the two splines from both sides of the panels during the insertion of fasteners, doubling the time needed for driving fasteners.

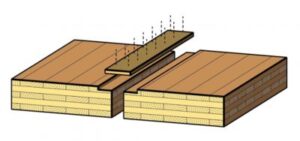

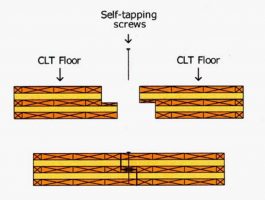

4. Half lapped joints

A half-lap joint consists of two workpieces reduced to half of their thickness where they lap over each other. It is commonly used after which long self-tapping screws are usually used to connect the panel edges. The joint can carry normal and transverse loads but is not considered to be a moment resisting connection.

To clamp the joint, apply wood glue to the 2 panel surfaces. Then, bring the glued surfaces tightly together with a small clamp. Place a scrap of wood on the joint faces to protect them from the clamp jaws.

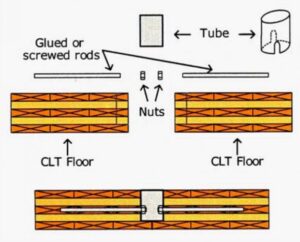

5. Tube connection system

In this system, a profiled steel tube with holes is used. The tube connector is inserted at those locations along the panel elements and the system is tightened on site using metal nuts.

Note that it is customary for the Structural Engineer of Record (SER) to be responsible for the design and detailing of mass timber connections. This is different from what is common practice for structural steel or glulam timber structures, where the SER indicates reactions or member forces and delegates connection design to the fabricator.

In need of expertise solutions for all your building concerns? Contact London Building Contractors

A Complete-Turnkey-Solution-For-You